-

HOME

-

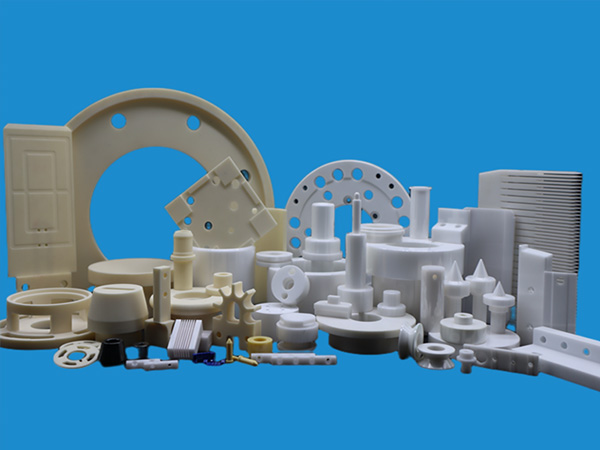

About UsCompany profileGuangdong Shuoqin new material Co., LTD At present, it has the leading ceramic materials and product production line in China, and has formed a variety of products dominated by structural ceramics and functional ceramics

-

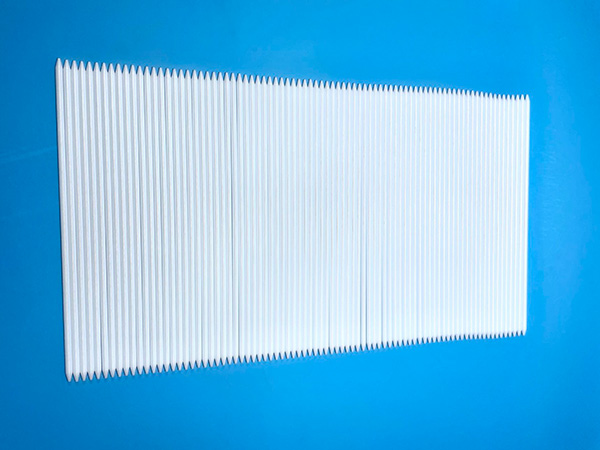

ProductsProductsWith leading ceramic materials and product production lines in China, it has formed a wide range of products dominated by structural ceramics and functional ceramics

-

ApplicationsApplicationsFocusing on the research and development of nanomaterials and optoelectronic products, it is one of the few manufacturers of special ceramic materials and products in China

-

Process

-

NewsNewsWith advanced forming, sintering, finishing Process, to form a number of professional production lines. Molding sintering, precision machining, testing equipment 120.

-

Contact Us

+86 13922968256